We do everything for job order filling

Together with the production of chemical-technical products, we offer job filling and packaging.

Experienced, diligent personnel ensure our customer’s products are filled into the requested packaging, labelling is GHS-compliant, packaging instructions which detail the pallet storage plan – and all on schedule.

For pure contract filling, we fill various chemical-technical products of different viscosities.

The strengths of our filling plant

- Filling chemical-technical products into tubes, cartridges, tubular bags, round-bottom bags, tins, bottles, canisters, pails, drums

- Coaxial, peeler or side-by-side cartridge filling

- Aerosol filling

- Labelling – all kinds of format and design (GHS conformity)

- Coding of batch number and expiry date

- Barcoding

- Set packaging

- Quality control according to relevant DIN regulations and customer requirements

- Filling of samples for testing or product market testing

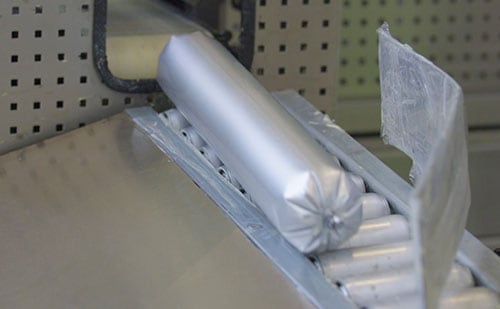

Example: hot-melt filling line

Our hot-melt filling line can fill hot adhesives from drums into cartridges, round-bottom bags, flat bags or tins of various sizes. By adding inert gas and a drying agent, even reactive, moisture-curing hot-melts can be filled and sealed with a ring-pull lid.

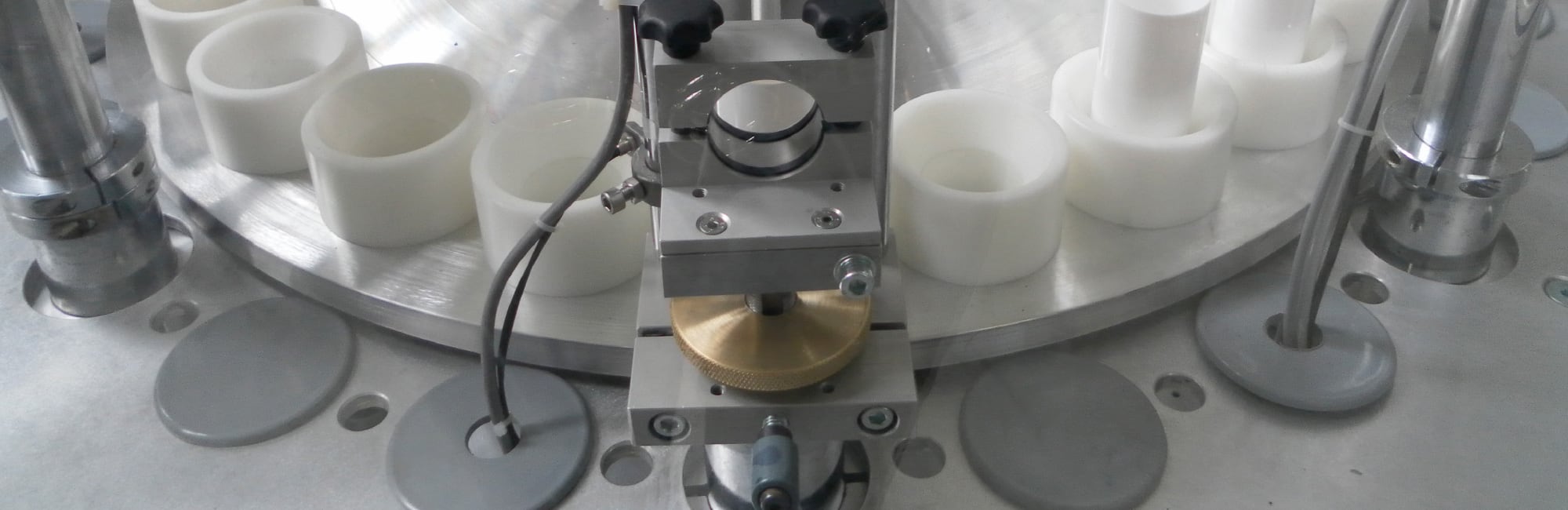

Example: cartridge filling line

Our cartridge filling line offers automatic filling, coding and labelling, with a daily output capacity of up to 10,000 cartridges.

Example: set packaging

From your components, we create a set!

As set packaging for our customers, we assemble various individual components into a ready-for-sale combination package. Our service ranges from managing the components, the filling, labelling and batching of individual parts, to the packaging of the completed set – for example in a bag, a cardboard box, etc. We handle all conceivable steps, you receive the set ready for sale – all in a single process.